DX Case #1

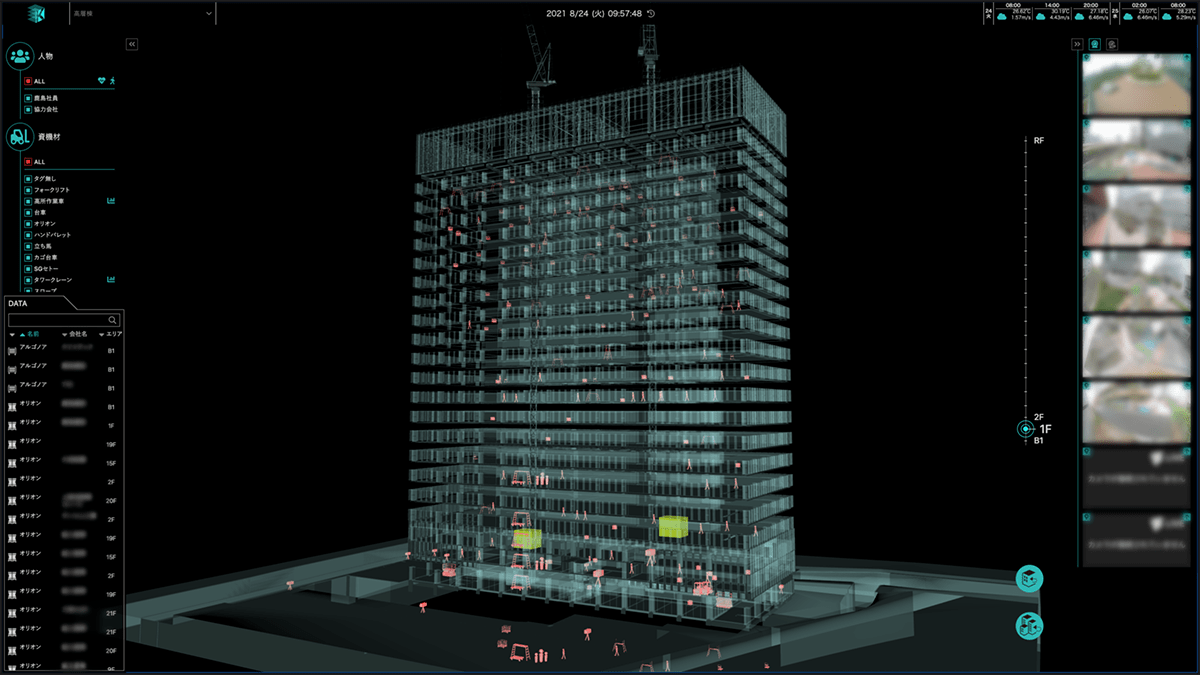

3D K-Field

Embodying the Future of "Construction DX"

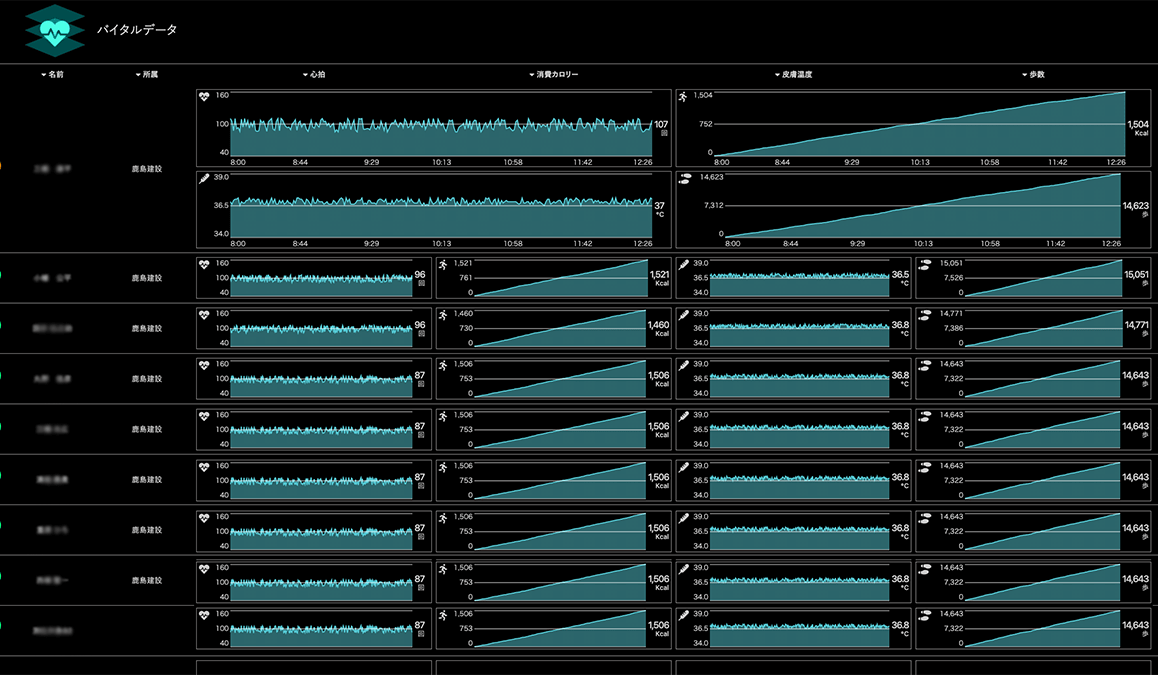

Real-time Construction Management

Challenger

With

課題

PROBLEM DEFINITION

Create a single picture that provides

a real-time bird's eye view

and grasp of the work site

Kajima Smart Production Vision

https://www.kajima.co.jp/news/press/201811/12a1-j.htm

Kajima Corporation's challenge was also a wall that the construction industry itself was confronting.

The company's challenge was to create an environment in which construction workers could work comfortably and proudly in the near future, when a chronic shortage of workers is expected to occur. On the other hand, the "2024 problem in the construction industry," as it has been called, is the impending application of the Workplace Workplace Reform Law, which will limit working hours.

To overcome this issue, Kajima Corporation formulated the "Kajima Smart Production Vision" in 2018, which aims to improve productivity by promoting the transformation of all production processes related to building construction, and is actively promoting digitalization, known as BIM (Building Information Modeling). Digital 3D architectural drawings and digital management tools for work processes were set at the core of the project, and analog processes were actively replaced with digital ones, including the introduction of robots, device-based positioning, and worker task management.

Convenience is a given.

An interface that is instantly understandable, convincing, and motivating.

Kajima Corporation had set a policy of "remoteness of 50% of work management operations by 2024. To this end, the company's mission was not only to collect and centralize work status data, but also to deploy work instructions to devices, for which various digital tools were introduced throughout the company.

On the other hand, no matter how sophisticated the tools are, if the interfaces are different, it will not lead to optimal overall efficiency. Communication costs for confirming details may rather increase. Above all, in order to instantly grasp "where I am currently in charge of the whole project and what I should do today," it is necessary to integrate each piece of digital information and express it in a single picture. Meetings called "inter-work liaison and coordination meetings" are held daily to unify this awareness and understanding of the work, and it is customary for each person to check various details while staring at the drawings distributed to them, under the explanation of the site supervisor. If this could be digitized for efficient coordination of awareness and immediate linkage of instructions and task management tool information, overall work efficiency and accuracy would be greatly enhanced.

Furthermore, Kajima Corporation's approach was a bit more oblique.

"The system must not only make workplaces more convenient, but it must also be cool."

Even with today's technological advances, working on a construction site is still a tedious job. The digital screen reflects the results of their work, and the huge structure they have created is beautifully visualized. In order for each one of us to perform our daily hard work with pride as a member of this grand project, "coolness" is an extremely important factor. Kajima Corporation intuitively understood that this would contribute to productivity as much as to work efficiency.

課題解決と挑戦

SOLUTION & CHALLENGE

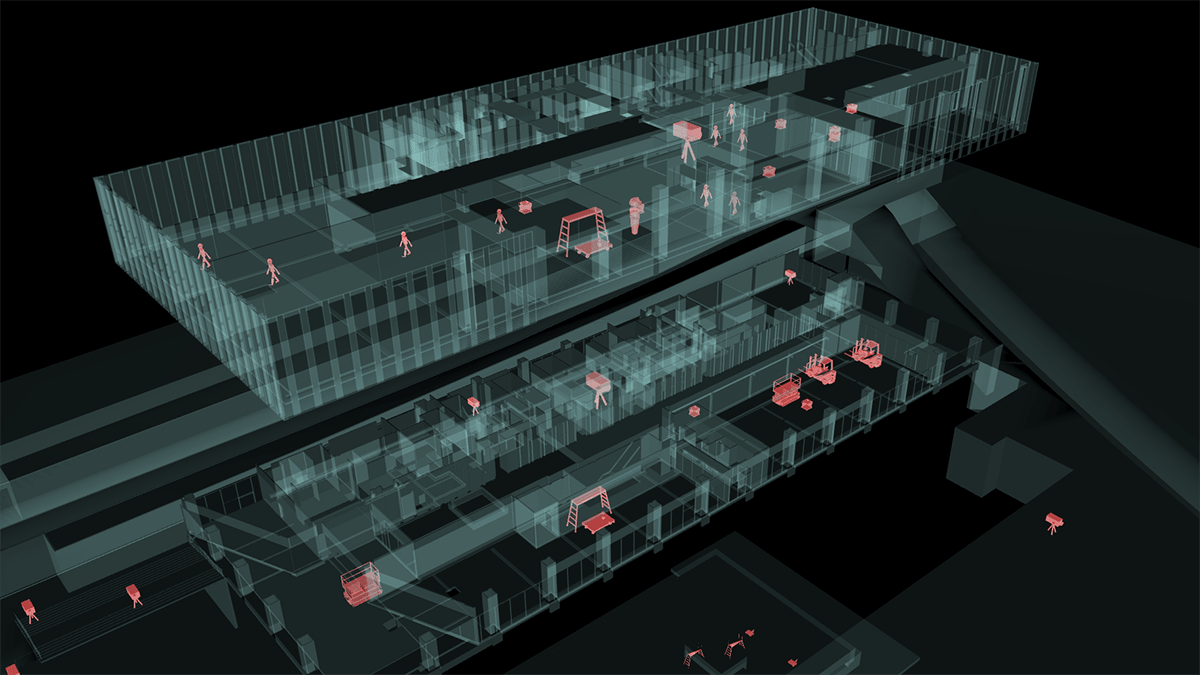

The architectural drawing and the work situation are the work situation into a single 3D model.

AsiaQuest was approached to participate in the realization of this "cool one-picture" concept because of the problem of converting K-Field, a one-picture system already in use by Kajima Corporation, into 3D.

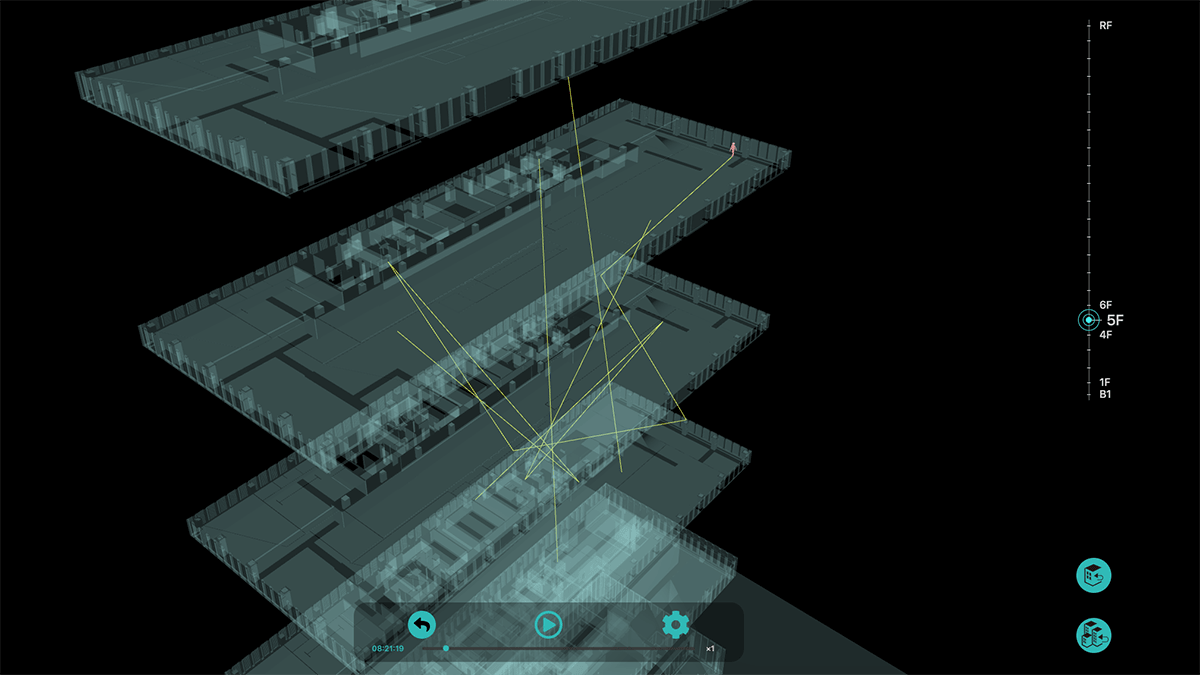

K-Field is a tool that combines a positioning function using GPS and positioning beacons, and was being used to monitor the status of various materials and equipment and construction workers and to collect progress data. However, because the map screen is 2D, it can only provide a two-dimensional view. To represent the entire picture of a construction site for a large structure such as a building, it was extremely important to create a 3D map. And the 3D map had to be able to be displayed on a browser. Installing a specific application would greatly reduce the versatility of the device.

In other words, the development of a tool that could represent a 3D model of a structure under construction on a browser, which could reflect positioning information in near real time. This was the challenge AsiaQuest faced.

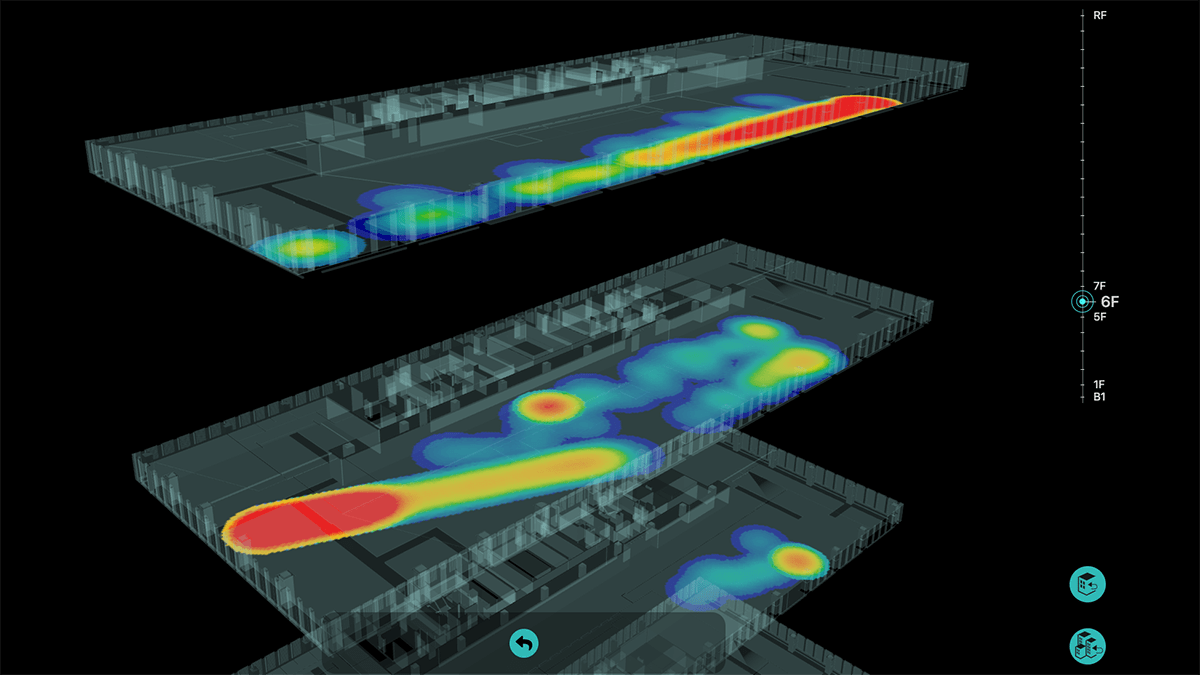

This task was based on the so-called "digital twin" concept. By creating a parallel world in which the real on-site situation is reflected directly in the digital world, it is possible to realize a management situation that is more intuitive and easy to grasp.

AsiaQuest began by creating a wireframe mockup of the 3D model, and using this as a starting point, repeated interviews were conducted, and various functional requirements were added. The client's philosophy, direction, and awareness of the issues were clear, but the specifications to be requested were still in a state of exploration. In the case of a conventional SI, the client would have asked for a requirements definition phase to finalize the specifications first, but AsiaQuest chose to avoid this and instead engage in a thousand-knock process with the client. There are many reasons for this. The traditional SI process takes too much time and is likely to be forcibly transformed into "what the SI side can do. If we want to pursue not only functionality but also coolness, it becomes essential to work out the look and feel and behavior in detail. We thought that it would be the shortest and most optimal way to achieve the result by repeating small-scale agile iterations to manifest and materialize the requirements at the same time. Above all, the engineer's pure desire to "create this wonderful view of the world together" was an extremely important factor.

Versatile, lightweight, and convergent

One of AsiaQuest's challenges in realizing the digital twin was the aforementioned micro-agile. One of AsiaQuest's challenges in realizing the digital twin was to manage the seemingly inefficient methodology of micro-agile development. The result was scrum-based development, but in the beginning it was a continuous process of trial and error. In a manner of speaking, it was a micro waterfall development and scrapping process that was repeated many times before reaching its final form, but as a result, it became a flexible and unique development method that is not bound by any mold or specification, and is now AsiaQuest's own main development process.

Another challenge was how to make the "heavy" process of 3D visualization and real-time reflection of positioning data lighter and smarter. After deep discussions in a dedicated project forum on Slack while concurrently working on development, the decision was made to develop the system in Three.js. Three.js is a library that makes it possible to control WebGL with JavaScript, which is not only efficient for development, but also highly versatile in terms of the browsers it can be used with, and its JS library Three.js is a library that makes it possible to control WebGL with JavaScript. React was also adopted for the development of various UI components. The framework's rich library and flexibility made it possible to create the necessary UI at high speed.

As for the rest, the models to be rendered and the processing of positioning data, I would only say that this challenge was the result of the convergence created by the thousand-knock method.

Finally, there is the challenge of visual design. The client's embodied image is the world of near-future science fiction films such as "Biohazard" and "Minority Report. Cyber and solid. Sophisticated geek. In order to grasp these nuances, I began by watching and researching science fiction movies that seemed to fit the bill. We did not take a cognitive engineering or design theory approach, but rather repeated trial and error, aiming to create a worldview that would "allow workers to feel like characters in a science fiction movie as they tackle the project. While ensuring usability and visibility as much as possible, which are the most important aspects of normal UI development, we are trying to create a "cool" construction site environment on the digital twin, and to make the participants feel "cool" as well.

仕組み

HOW IT WORKS

Users can see at a glance who is working where in the overall view, and can freely choose between overhead or close-up views. The user can also specify work areas and visualize hazardous areas by displaying marks in specific areas.

As mentioned above, front-end development was done with Three.js for 3D rendering and React for UI creation. Back-end development is done in Laravel (PHP), and AWS is adopted as the server environment.

In inter-work liaison and coordination meetings where details of on-site work are checked daily, if various instructions are given using 3D K-Field, the people involved in the work can link their own workplaces while looking at the whole picture, enabling them to intuitively grasp the situation. Even if the site supervisor is at a different site, he or she may be able to explain the situation remotely. To put it another way, it will be possible in the future for each person in charge to participate in liaison meetings without having to leave their respective posts.

In this way, 3D K-Field represents a "digital twin" world in which the actual work site can be intuitively grasped digitally, with the aim of promoting understanding of the work site and realizing progress management via remote control.

Key Technologies

主要活用技術

- JavaScript

- React(TypeScript)

- AWS

- Laravel(PHP)

About AsiaQuest, Inc.

AsiaQuest is a "digital integrator" that supports corporate DX. We do not only provide ordinary system integration, but also provide consulting services to help our clients think about DX together, and design, develop, and operate systems that make full use of digital technologies necessary for DX.

We have specialized technology teams in the digital fields of IoT, AI, Cloud, Mobile, Web, and UI/UX, and we can put together the most appropriate project team to achieve the client's goals. We are capable of speedy response from implementation of PoC to verification of effectiveness of business models and technical issues to construction of large scale systems for digitalization.